All About Sandblasting Aluminum

Wiki Article

The Greatest Guide To Sandblasting Alternatives

Table of ContentsSandblasting Machine Fundamentals ExplainedWhat Does Sandblasting Aluminum Do?The Facts About Sandblasting Adalah UncoveredHow Sandblasting Machine can Save You Time, Stress, and Money.The Basic Principles Of Sandblasting At Home

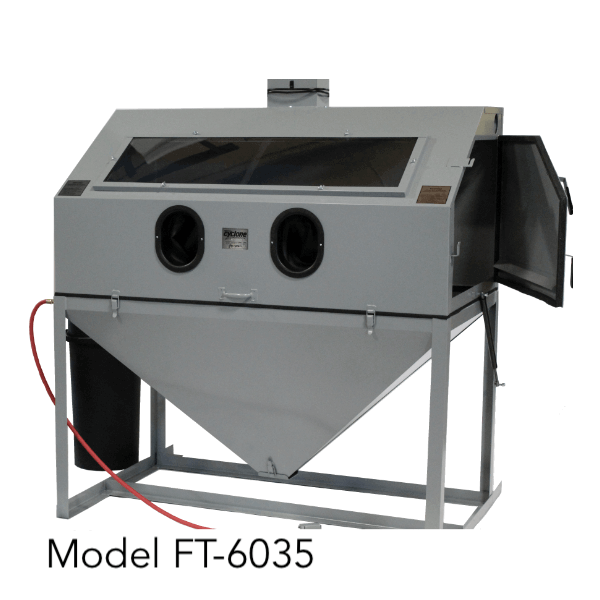

Portable applications might or might not reuse the abrasive. A blast cabinet is basically a shut loop system that permits the operator to blow up the component as well as reuse the abrasive. It typically includes 4 parts; the control (cabinet), the rough blowing up system, the unpleasant recycling system as well as the dust collection.Automated blast cupboards are also made use of to process large amounts of the exact same component and may incorporate multiple blast nozzles and also a part conveyance system. There are three systems generally made use of in a blast closet. Two, siphon and also stress, are dry and one is wet: A siphon blast system (suction blast system) utilizes the compressed air to create vacuum cleaner in a chamber (understood as the blast weapon).

The abrasive blend travels through a nozzle that guides the fragments towards the surface area or workpiece. Silicon carbide as well as boron carbide nozzles are much more use immune and also are typically used with harder abrasives such as aluminium oxide.

Sandblasting Air Compressor Things To Know Before You Get This

Each application may need the usage of several tools, however, there are numerous key elements that can be located in a common blast space: An unit or control system, generally the area itself, developed to remain closed to avoid blast media from escaping A blowing up system; wheel blasting as well as air blasting systems are generally used A blast pot a pressurized container filled up with unpleasant blowing up media A dirt collection system which filterings system the air in the space and also prevents particulate matter from escaping A product recycling or media reclamation system to collect abrasive blasting media so it can be utilized once again; these can be automated mechanical or pneumatic systems set up in the floor of the blast room, or the blast media can be accumulated by hand by sweeping or shovelling the material back into the blast pot Extra devices can be included for ease and also boosted use, such as overhanging cranes for manoeuvring the workpiece, wall-mounted devices with multiple axes that permit the driver to get to all sides of the work surface, and also sound-dampening products utilized to minimize sound levels.

Mineral: Silica sand can be utilized as a type of mineral look at here now abrasive. It often tends to break up quickly, creating huge amounts of dust, exposing the driver to the possible advancement of silicosis, a devastating lung illness. To counter this risk, silica sand for blowing up is commonly covered with resins to control the dust.

A Biased View of Sandblasting And Painting

Silica is a typical abrasive in nations where it is not prohibited. Another common mineral abrasive is garnet. Garnet is much more costly than silica sand, but if used appropriately, will offer equal manufacturing prices while creating less dust and also no safety and security risks from consuming the dust. Magnesium sulphate, or kieserite, is often used as a choice to baking soda.

Several customers agree to pay added for denims that have the appearance of being utilized. To offer the fabrics the ideal used appearance sandblasting is used. Sandblasting has the risk of creating silicosis to the employees, and also in Turkey, more than 5,000 employees in the fabric industry struggle with silicosis, and 46 people are understood to have actually passed away from it.

Sandblasting And Painting Near Me Can Be Fun For Everyone

's Fair Profession Center carried out a survey amongst 17 textile firms that showed really few were mindful of the threats triggered by manually sandblasting pants. A number of companies claimed they would certainly abolish this technique from their own manufacturing.Stucco Young boy offers sand blasting or poly preparation services as needed actions on re-stuccoing your home. The current problem of your stucco walls are the figuring out element of what procedure is best for you. Both processes come with a life time warranty as well as create a structurally sound substrate for the top layer to stick to. sandblasting aluminum.

Sandblasting is additionally understood as rough blowing up. Generally, it is the procedure of forcibly driving a stream of abrasive material published here against a surface. The sandblasting procedure is done under high stress to smooth a harsh surface area, roughen a smooth/Shape the surface area to eliminate its contaminants. There are numerous variants of sandblasting process like bead blasting, Soda blasting and shot blasting.

The Of Sandblasting Air Compressor

If your job account belongs to sandblasting or you owned a company that associated with the same process, you need to remain with us. In this write-up, we will discuss sand blasting devices materials as well as its pros and corns. Prior to it, allow me likewise clear some of the details of its procedure.- This process is finest fit for metal surfaces, to stop dampness accumulation and also prevent water intrusion in the surface. Sandblasting is the procedure of thrusting unpleasant by utilizing the pressurized fluid or compressed gas as propellant. There are many common terms for this procedure that is usually connected to the sandblasting abrasive media made use of for this process.

Report this wiki page